Views: 0 Author: Site Editor Publish Time: 2025-12-29 Origin: Site

PCB fabrication is complex. Even with advanced tools, mistakes can happen. These errors can delay projects, increase costs, and cause product failure.

In this guide, we will explore common PCB mistakes and provide solutions. Fixing these issues ensures your boards are reliable and successful.

Learn more about our products at Ruomei Electronic.

Gerber files are essential for PCB fabrication. These files contain detailed instructions for the PCB manufacturer on how to etch the copper traces, drill holes, apply solder mask, and print silkscreen layers. Missing layers or corrupted files can halt the entire production process, leading to costly delays and design revisions.

Gerber File Component | Description |

Copper Traces | Defines the electrical connections on the PCB |

Solder Mask | Protective coating that prevents solder bridges |

Silkscreen | Printed layer that marks component locations and labels |

Drill Data | Specifies hole locations and sizes for vias and components |

Ensure your Gerber files include all necessary layers, including copper traces, solder mask, silkscreen, and drill data. Perform Design for Manufacturing (DFM) checks early to catch potential file issues before sending the files to the manufacturer. By using industry-standard CAD tools that generate IPC-compliant Gerber files, the risk of errors can be minimized.

To avoid mistakes, it’s essential to collaborate closely with your PCB manufacturer during the design phase. They can provide input on specific file requirements and check for issues before production begins. If possible, leverage automated file validation tools to double-check the accuracy of your files.

The Bill of Materials (BOM) lists all components required for the PCB assembly process. Inaccurate or incomplete BOMs can lead to sourcing wrong parts, assembly delays, and even functionality issues in the final product. Therefore, accuracy in this document is vital to ensure that the right components are available at the right time.

Common BOM Error | Solution |

Incorrect part numbers | Cross-reference with schematic and supplier data |

Incompatible components | Verify compatibility before submission |

Missing components | Perform a thorough review with design team |

Before sending your BOM to the manufacturer, review it for accuracy. Cross-reference part numbers, component availability, and compatibility with your design. An effective BOM validation process includes verifying part specifications and availability from trusted suppliers.

Tip: Maintain a master component library and regularly update it to avoid obsolescence issues and ensure all components are still in production.

To improve the accuracy of your BOM, implement automated validation tools that can check for part mismatches and inconsistencies. Also, communicate regularly with your supplier to confirm that all parts are available and in stock.

Incorrect solder paste application is one of the most common issues in PCB assembly. This can lead to a variety of defects, including weak solder joints, short circuits, and component tombstoning. Each of these issues can compromise the reliability of the board, affecting its overall performance and longevity. If these defects are not addressed early in the assembly process, they could ultimately result in product failure, causing delays, increased costs, and dissatisfied customers.

To prevent solder paste issues, it's essential to ensure that stencil data is accurate. Review the pad sizes and solder mask openings to confirm they are correctly defined. Pay close attention to the pad-to-aperture ratios, as these directly affect the volume of solder paste applied. Also, design the component layout with sufficient spacing to avoid paste bridging and tombstoning risks. By optimizing these aspects during the design phase, you can reduce the chances of assembly failures and improve the quality of the final product.

A successful soldering process requires precision and control. It's important to work closely with your PCB manufacturer to understand their soldering requirements and ensure that the assembly process follows best practices. By maintaining consistent paste application and ensuring proper placement and alignment of components, you can achieve high-quality solder joints that will enhance the overall reliability of the board. Additionally, monitoring and controlling the solder paste application process throughout the production cycle can help prevent defects and reduce the need for costly rework or repairs.

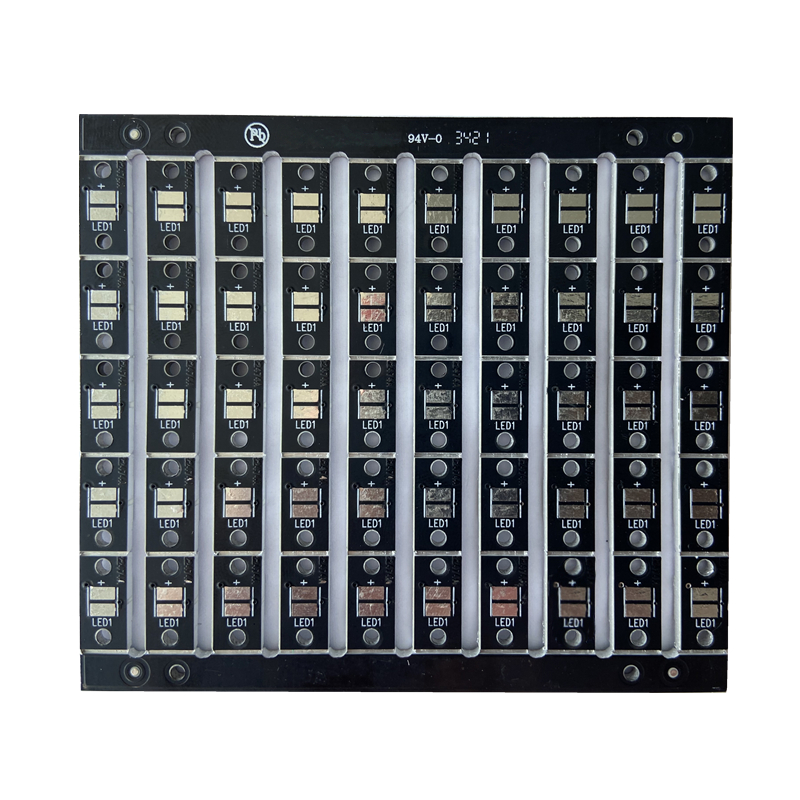

Component placement is a crucial step in PCB fabrication. Misaligned components or incorrect orientation during the pick-and-place operation can lead to assembly failures. These mistakes can even cause damage to expensive components. Improper placement can affect the overall performance, durability, and functionality of the PCB, potentially leading to costly redesigns or project delays.

To prevent errors, always double-check that the footprints in your PCB layout match the component datasheets precisely. The orientation of components is essential, especially for polarized components like diodes, electrolytic capacitors, and other sensitive parts. Ensure that clear polarity and orientation markings are included in the design, particularly on the silkscreen layer, so that the assembly team can easily verify the component alignment during the pick-and-place process.

A well-organized layout is essential to avoiding misplacement errors. Following standard placement guidelines ensures that components are correctly spaced and aligned. Leave enough room for pick-and-place tolerances and ensure there is sufficient space around components to avoid overlap during the assembly process. This approach helps reduce the risk of errors and ensures smoother, more efficient assembly, ultimately improving the overall quality of the PCB.

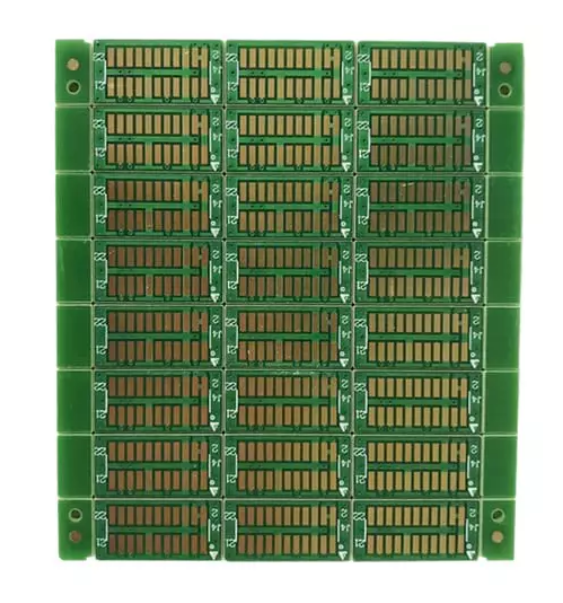

Uneven copper distribution across PCB layers can lead to mechanical stress, which may cause warping or delamination during fabrication. These issues can significantly affect the board’s integrity and reliability. Improper copper balancing can result in functional problems in the final product, affecting performance and durability.

To prevent copper imbalance, use copper thieving techniques. This involves strategically adding extra copper areas in certain places to balance the copper density throughout the board. Symmetrical copper patterns across all layers also help minimize mechanical stress. Collaborating closely with your PCB manufacturer is essential to ensure their specific requirements are met during production.

It's important to consult your PCB manufacturer to understand their copper balancing needs. Before finalizing the design, use simulation tools to visualize and analyze the copper distribution. This can help detect potential issues before they arise in the fabrication process, ensuring the board remains structurally sound and performs optimally.

Pad cratering and via failures are common issues in PCB fabrication. These problems often arise due to poor drilling quality or the selection of inappropriate materials. When drilling is not executed correctly, or the materials do not meet the required standards, pads can lift during soldering. Additionally, unreliable vias can create weak connections that compromise the overall functionality and performance of the PCB.

To avoid these issues, ensure your manufacturer follows IPC-6012 standards for via formation. These standards are designed to ensure that vias are created with the proper quality and structural integrity. It is also essential to specify high-quality PCB materials that are suited to the demands of your specific application. Alongside this, verify that drilling parameters are properly set up according to the design requirements. This proactive approach can significantly reduce the likelihood of pad cratering and via problems.

Maintaining pad integrity and ensuring high-quality via formation is critical for reliable PCB performance. Controlled impedance testing is an effective method to check the quality of vias and pads before moving on to the final stages of assembly. By implementing strict quality control measures throughout the production process, manufacturers can identify potential issues early, ensuring that the final product is free from defects and performs as expected.

Design rule violations occur when your PCB design exceeds the manufacturer’s capabilities. These violations often involve issues like trace width, spacing, hole sizes, or the number of layers. Such violations can result in expensive redesigns or delays during manufacturing, leading to increased production costs.

Design Rule | Typical Violation | Best Practice |

Trace Width | Too narrow trace width for current handling | Follow manufacturer’s recommended trace width |

Hole Size | Hole diameter exceeds the manufacturer’s capabilities | Consult with manufacturer for hole size limits |

Layer Count | Exceeds manufacturing capabilities | Verify layer count limitations early |

To avoid violations, begin by reviewing the design rule documents provided by your PCB manufacturer. Implement design rule check (DRC) files into your CAD system to ensure compliance with the manufacturer’s specifications.

Early access to design rule documents from your manufacturer is essential. This will help you avoid violations that could complicate production and increase costs. By ensuring your design aligns with the manufacturer’s guidelines, you can minimize the risk of errors and keep the project on track.

Conductive Anodic Filamentation (CAF), corrosion, and thermal cycling are major concerns that can severely compromise the long-term reliability of your PCB. These environmental factors contribute to gradual degradation, ultimately affecting the PCB’s performance and lifespan, especially when exposed to harsh conditions. Over time, this can lead to product failures, increased maintenance costs, and reduced reliability.

To protect PCBs from environmental stress, applying conformal coatings is an effective solution. These coatings act as a barrier, protecting the PCB from moisture, dust, and contaminants. Additionally, selecting PCB materials with appropriate glass transition temperatures ensures they can withstand thermal and environmental fluctuations, reducing the risk of failure over time.

In environments with high humidity or extreme temperatures, it’s crucial to design PCBs with moisture-resistant materials. These materials will help prevent water absorption, which can cause long-term damage. Proper spacing between components is also essential, as it reduces the risk of short circuits or overheating. By incorporating these design considerations, you can enhance the longevity and reliability of your PCBs in challenging conditions.

In conclusion, avoiding common PCB fabrication mistakes is crucial for improving reliability and performance. Proactive planning and collaboration with experienced manufacturers lead to successful production. By implementing best practices, you can avoid costly errors. Ruomei Electronic offers high-quality PCB solutions, ensuring your products meet the highest standards and deliver exceptional value.

Tip: A successful PCB fabrication process requires attention to detail and constant communication with your manufacturing partner. Make sure to implement thorough DFM checks and pre-production validations to ensure the best results.

A: Common PCB fabrication mistakes include incorrect Gerber files, BOM errors, improper solder paste application, and component misplacement. These mistakes can lead to delays, increased costs, and product failure.

A: Ensure your stencil data is accurate, check pad sizes and solder mask openings, and maintain proper pad-to-aperture ratios. This will help prevent solder issues like weak joints and tombstoning.

A: Copper balancing issues arise from uneven copper distribution across layers, which can cause mechanical stress and lead to warping. Symmetrical copper patterns and copper thieving techniques can help prevent this.

A: A well-designed PCB, free of fabrication errors, reduces rework and material wastage, ultimately lowering production costs. Proper planning and early reviews are key to cost-effective PCB manufacturing.