Views: 0 Author: Site Editor Publish Time: 2025-12-22 Origin: Site

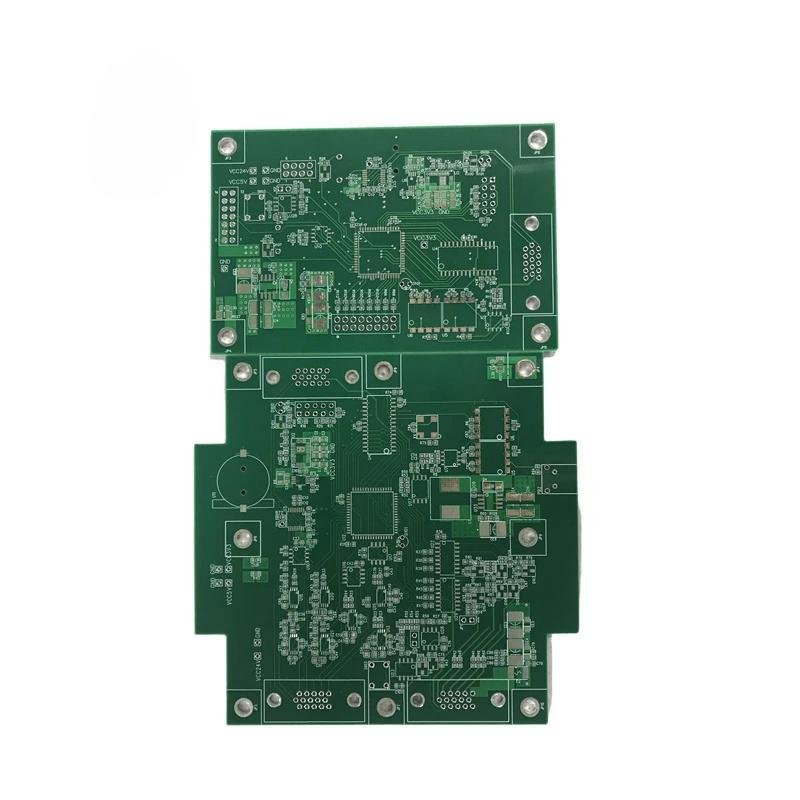

Designing a Printed Circuit Board (PCB) is critical in electronic device development. Whether for simple gadgets or complex systems, the PCB layout impacts your product's performance. As devices grow more complex, layout considerations become crucial for reliability and efficiency.

This article explores the key factors to consider when designing a PCB layout. You’ll learn about component placement, signal integrity, and power distribution.

At Ruomei Electronic, we provide high-quality PCBs to meet modern electronics' needs. Learn more about our products today.

The number of layers in your PCB will directly affect its functionality and complexity. A single-layer board is simpler and typically used for low-cost products, where minimal components are required. It is common in basic consumer electronics, such as toys or simple gadgets. Multi-layer boards, on the other hand, are ideal for more advanced electronics. These boards allow for more complex designs and better signal integrity by providing additional layers for routing power and signals without overcrowding the design. However, multi-layer PCBs are more expensive to manufacture due to the added complexity and materials involved.

Vias are critical for creating electrical connections between different layers of the PCB. There are several types of vias, including blind vias, buried vias, and microvias. Blind vias connect outer layers to inner layers but do not go all the way through the board. Buried vias are only found within inner layers and do not reach the outer layers. Microvias are smaller and are typically used for high-density, fine-pitch designs. Understanding which via type to use is essential for optimizing design efficiency and cost. Minimizing via usage when possible can help reduce manufacturing complexities and potential performance issues, especially when working with high-speed circuits.

The thickness of the PCB traces plays a significant role in the current-carrying capacity and overall reliability of the circuit. The trace thickness must align with the expected electrical current to avoid overheating or potential failure. Incorrect trace thickness can lead to lamination issues during manufacturing or soldering problems during assembly. For high-current applications, consider using thicker copper traces, or opt for additional layers to accommodate the current load while maintaining performance. Choosing the right PCB material, such as FR4 or other specialty materials, is also vital to ensure proper performance under varying environmental conditions.

Proper component placement is essential for ensuring the functionality, reliability, and ease of manufacturing of your PCB. Components should be strategically placed to minimize trace lengths, as longer traces can introduce delays, noise, or signal integrity issues. Group components by their function to reduce interference. For example, analog components should be kept separate from digital components, and power components should be placed in areas that reduce heat buildup. Additionally, placing components in areas that allow for efficient routing will not only improve performance but also make the PCB easier to assemble and test. Prioritizing the thermal management of components, such as ensuring adequate space around heat-sensitive areas, is also important for the long-term durability of the PCB.

PCB Layer Type | Description | Common Applications |

Single-layer PCB | Copper traces on one side of the board. | Low-cost, simple devices, toys |

Double-sided PCB | Copper traces on both sides of the board. | Consumer electronics, audio devices |

Multi-layer PCB | Multiple layers stacked together for complex circuits. | High-performance electronics, medical devices, computers |

Signal integrity is crucial in high-speed electronics, where even the slightest distortion can lead to data loss or performance issues. Proper management of factors like rise and fall times, trace lengths, and impedance is essential for maintaining signal clarity. Impedance mismatches can cause reflections and signal degradation, which affects overall performance. Ensuring short, well-routed signal traces reduces the risk of unwanted interference. It’s also important to keep digital and analog signals separated to avoid cross-talk. Using simulation tools during the design phase can help identify potential signal integrity issues, especially in circuits operating at higher frequencies.

Power integrity refers to the reliable distribution of power across the PCB to all components. It ensures that the components receive a steady, noise-free power supply, which is essential for the stability and performance of the device. Poor power distribution can result in voltage drops, excessive heat, or even component failure. For high-performance designs, it's important to carefully plan the power distribution network (PDN) to ensure that high-current paths are efficiently managed. Additionally, ensuring a low impedance ground plane can help minimize noise and ensure stable power delivery to all components. A well-designed PDN not only enhances the performance but also extends the life of your device.

Practice | Description | Importance |

Impedance Control | Maintaining a consistent impedance across traces. | Prevents signal reflection and data loss. |

Minimizing Trace Length | Keep traces as short as possible. | Reduces delay and signal degradation. |

Using Ground Planes | Add solid ground planes for better return paths. | Minimizes noise and electromagnetic interference. |

Ensuring that your PCB is easy to manufacture is crucial for controlling costs and minimizing errors. By adhering to Design for Manufacturability (DFM) principles, you can optimize the design process. Key guidelines include maintaining proper component spacing, avoiding overly complex geometries, and selecting common, standardized components. These practices help prevent issues during fabrication, ensuring smooth production processes and minimizing costly revisions. Always consult with your PCB manufacturer early in the design phase to ensure the design aligns with their manufacturing capabilities and any constraints they may have.

Choosing the right components is not just about functionality, but also about availability and cost-efficiency. Opting for widely available components reduces delays and ensures that the product can be manufactured at scale without encountering supply chain disruptions. Before finalizing the design, verify that all components are in stock and easily sourced. Avoid using parts that are obsolete or difficult to find, as this can cause production bottlenecks or drive up costs. A proactive approach to component selection ensures a smoother, more cost-effective manufacturing process.

DFM Guideline | Description | Benefit |

Component Spacing | Ensure enough space between components. | Avoids shorts and makes assembly easier. |

Avoid Complex Geometries | Keep designs simple and avoid overly complex shapes. | Reduces errors and manufacturing costs. |

Standardized Components | Use commonly available and standard components. | Easier sourcing, reduces lead time. |

Testing the PCB both during and after the layout process is critical to ensure that it performs as expected. This includes electrical testing, impedance checks, and signal integrity assessments. Use both pre- and post-layout testing to catch any potential design flaws early, ensuring that the PCB is fully functional before mass production begins.

Choosing environmentally friendly PCB materials is becoming increasingly important due to growing concerns about sustainability. Selecting materials that comply with environmental regulations, such as RoHS (Restriction of Hazardous Substances), is essential for ensuring that your PCB meets industry standards and reduces environmental harm. By using compliant materials, you help minimize hazardous waste and contribute to a greener, more sustainable electronics industry. Additionally, this can improve your product's marketability, as more consumers and industries prioritize environmentally responsible manufacturing practices.

In certain industries, such as automotive, medical, and aerospace, PCBs must adhere to specific regulatory standards to ensure safety and performance. These regulations often include strict requirements for materials, manufacturing processes, and testing procedures. Understanding and integrating these standards into your design process can prevent costly redesigns and certification delays down the road. By consulting regulatory guidelines early in the design phase, you can ensure that your PCB meets the necessary compliance criteria, reducing the risk of non-compliance and facilitating smoother certification and market entry.

A PCB layout designed with scalability in mind ensures long-term usability and reduces the need for costly redesigns. By anticipating future needs, you can add extra layers or provide more space for additional components. This approach not only helps in accommodating new technologies but also simplifies upgrades as they arise. Designing with modularity in mind allows for easy updates or changes without requiring a complete overhaul of the entire layout, making your design more flexible and adaptable over time.

As technology continues to evolve rapidly, PCB layouts must adapt to meet new requirements. Emerging technologies, such as 5G, artificial intelligence (AI), and the Internet of Things (IoT), require PCBs capable of handling faster speeds, more complex functionality, and more compact designs. Keeping up with these advancements ensures your PCB design remains relevant for upcoming applications. It’s essential to stay updated on industry trends and new technologies to ensure your PCB can efficiently support the demands of tomorrow’s devices.

When designing a PCB layout, attention to detail is essential for creating a reliable and manufacturable design. By considering factors like layer stack-up, via types, trace thickness, component placement, and signal integrity, you can ensure a high-quality PCB. Collaborating with your PCB manufacturer early helps avoid costly mistakes. Following these considerations will optimize your design for performance and cost-effectiveness.

Ruomei Electronic offers high-quality PCBs that meet the needs of modern electronics, ensuring your designs perform reliably and efficiently.

A: When designing a PCB layout, consider layer stack-up, via types, trace thickness, component placement, and signal integrity to ensure a reliable and efficient design.

A: Proper component placement minimizes interference, reduces noise, and ensures optimal functionality by grouping similar components and optimizing trace lengths.

A: Signal integrity ensures that electrical signals remain clear and accurate, preventing data loss or distortion, especially in high-speed circuits.

A: Optimize the PCB layout by minimizing complex designs, selecting standard components, and ensuring manufacturability to reduce production costs and avoid delays.