Views: 0 Author: Site Editor Publish Time: 2025-12-17 Origin: Site

Printed Circuit Boards (PCBs) are the unsung heroes of modern electronics. Without them, the technology we rely on daily would not exist. From the smallest wearables to large industrial machines, PCBs make everything work.

In this article, we will explore how PCBs power devices in various industries. You’ll learn about their essential role in consumer electronics, medical devices, and beyond.At Ruomei Electronic, we understand the importance of high-quality PCBs in making your devices reliable and efficient. Learn more about our products and how they can enhance your projects.

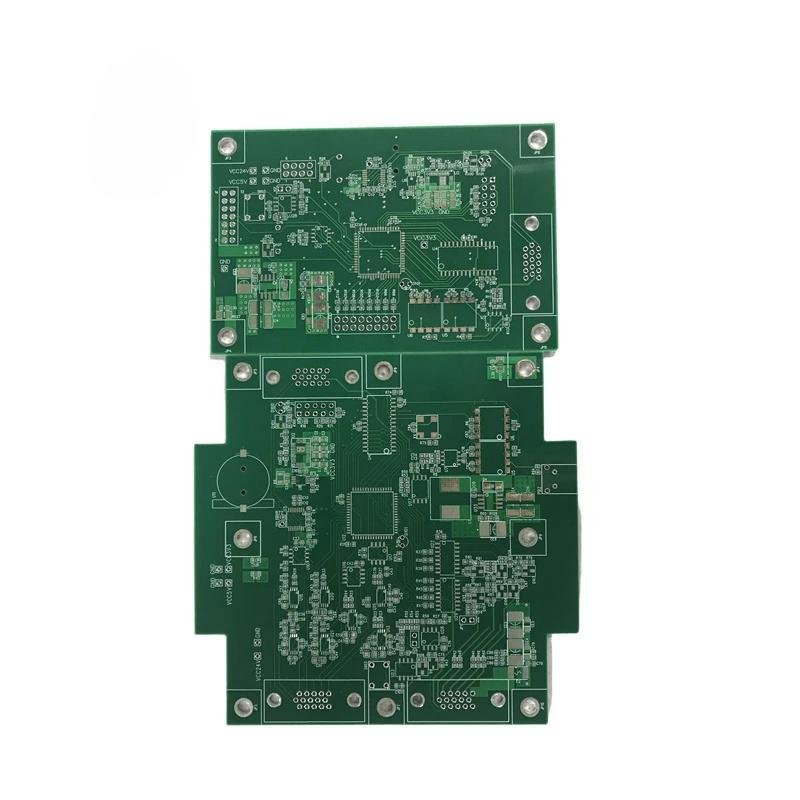

At its core, a Printed Circuit Board (PCB) is a board used to mechanically support and electrically connect electronic components. These boards are composed of conductive copper traces laminated onto a non-conductive substrate. These traces form the electrical pathways that route signals and power between components like resistors, capacitors, and microprocessors. PCBs are at the heart of nearly every modern electronic device, acting as the brain that connects all the moving parts of a device.

The introduction of PCBs significantly reduced the need for bulky wiring, making electronics smaller, faster, and more efficient. Before PCBs, electronic devices were often filled with tangled wires that were difficult to manage and prone to failure. With the advent of PCBs, manufacturers could create compact, reliable, and high-performance products.

From their humble beginnings in the 1950s to their current status in advanced electronics, PCBs have undergone significant advancements. Today, PCBs come in many types and configurations, allowing for innovations in everything from smartphones to spacecraft. The complexity and capabilities of PCBs continue to evolve, providing the backbone for the technology that shapes our world.

Every smartphone or tablet you use is powered by a series of PCBs. These boards house critical components that allow your device to function. From the display to the battery, and even the wireless communication systems, PCBs are responsible for making these devices slim, functional, and efficient.

The computer you're reading this article on likely contains multiple PCBs. The main system unit, keyboard, monitor, and storage devices all contain PCBs that manage the processing, power, and data transmission. Without PCBs, the modern computer as we know it would not exist.

Wearable devices like fitness trackers and smartwatches also rely on compact PCBs. These devices require miniaturized, high-performance boards that can fit in small spaces without sacrificing performance. The small size of these PCBs makes it possible to integrate advanced technology into sleek, portable designs.

Device Type | PCB Type Used | Main Function | Key Features |

Smartphones | Multi-layer PCBs | Power management, signal routing | Compact, lightweight, flexible |

Laptops/Computers | Multi-layer & Rigid PCBs | Data processing, signal transmission | Durability, high-speed performance |

Tablets | Flexible PCBs | Display, touch functionality | Space-saving, high-density |

The rise of smart home devices, such as thermostats, voice assistants, and security cameras, has been made possible thanks to PCBs. These boards enable communication, data processing, and power management, transforming everyday objects into intelligent devices that can be controlled remotely.

Even your microwave or refrigerator is powered by PCBs. These household staples, which are often overlooked in discussions about electronics, rely on PCBs to manage temperature settings, control sensors, and provide efficient operation. The integration of PCBs into these devices has helped make them more reliable and energy-efficient.

In the kitchen, devices like coffee makers, blenders, and toasters are powered by PCBs. These compact boards not only ensure proper function but also contribute to the sleek, modern designs of kitchen appliances.

Appliance | PCB Function | Specific Role in Functionality |

Microwave | Control PCBs | Power regulation, heat management |

Refrigerator | Temperature PCBs | Cooling system regulation, energy efficiency |

Coffee Makers | Circuitry PCBs | Brewing control, safety mechanisms |

PCBs are essential in medical devices such as heart rate monitors, pacemakers, and diagnostic equipment. These devices must meet rigorous standards for precision, cleanliness, and reliability because even the smallest error could have serious consequences. The accuracy and efficiency of medical PCBs ensure patient safety and improve healthcare outcomes.

Medical-grade PCBs undergo strict quality control processes. They must be designed to perform flawlessly over long periods, often in challenging environments. The materials and design of these PCBs are critical to the safety and effectiveness of medical equipment.

As technology continues to advance, the role of PCBs in healthcare is expanding. Future developments may include more compact designs, enhanced biocompatibility, and the integration of advanced sensors for real-time monitoring.

In aerospace, PCBs must endure extreme temperatures, radiation, and vibration. They are used in critical systems like navigation, communication, and control panels. The reliability and performance of these PCBs are non-negotiable, as any failure could jeopardize the safety and success of a mission.

Application | PCB Type Used | Main Function | Key Requirement |

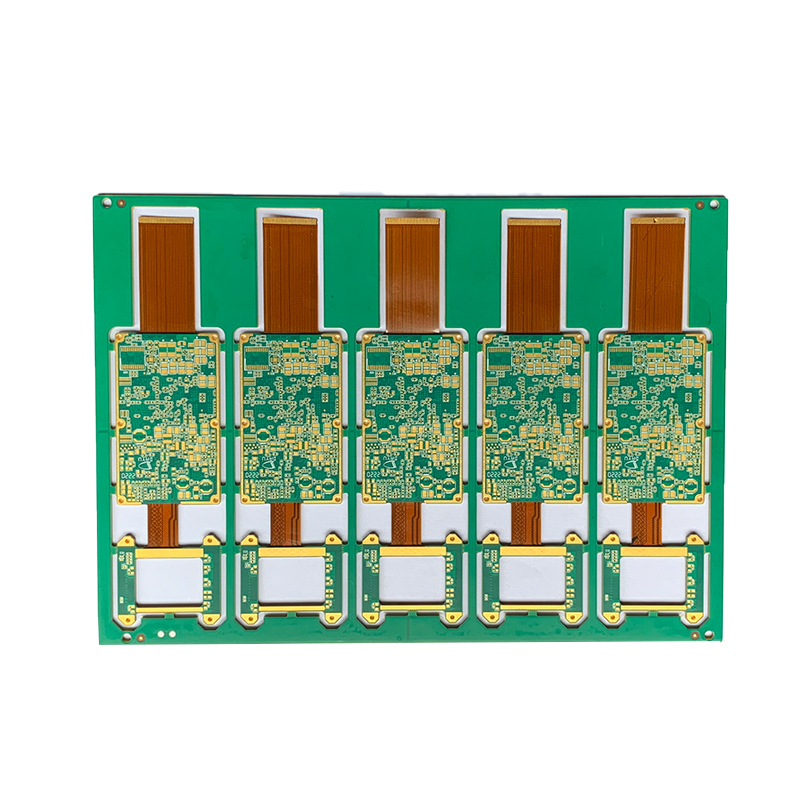

Aerospace Navigation | Rigid-flex PCBs | Navigation, flight control systems | High reliability, temperature resistance |

Military Communication | Military-grade PCBs | Secure, reliable communications | Durability under extreme conditions |

PCBs used in military applications must meet stringent standards for durability and performance under harsh conditions. These boards are used in systems such as guidance systems, radar, and communications, where failure is simply not an option.

As aerospace and defense technologies evolve, the demand for advanced PCBs will increase. Innovations in flexible PCBs and high-performance materials will continue to play a critical role in ensuring the success of military and aerospace operations.

Electric and autonomous vehicles are packed with electronics that rely on PCBs for everything from battery management to safety features. These vehicles depend on the high-performance capabilities of PCBs to manage complex systems efficiently.

The automotive industry is increasingly relying on PCBs to power systems like advanced driver assistance systems (ADAS), infotainment, and safety modules. These boards must be rugged, resistant to heat, moisture, and vibration, and capable of delivering consistent performance over time.

Automotive PCBs must endure extreme environmental conditions, such as temperature fluctuations, moisture, and vibration. The ruggedness and reliability of these PCBs ensure that automotive systems perform reliably throughout the life of the vehicle.

Telecommunications equipment, such as routers, modems, and mobile base stations, depend on PCBs to transmit and receive signals. These boards are designed to handle high-frequency signals with minimal interference, ensuring seamless communication in an increasingly connected world.

5G networks rely heavily on advanced PCB technology to manage the high data throughput and low latency requirements. As 5G technology continues to roll out, the demand for specialized PCBs will increase, supporting the infrastructure that powers next-gen communication.

As telecom infrastructure evolves, we can expect PCBs to become even more specialized. Innovations in materials, design, and manufacturing processes will enable telecom systems to support higher speeds, greater reliability, and more extensive connectivity.

PCBs are not just for high-tech gadgets; they are integral to a vast array of devices and systems that we rely on every day. From medical devices to automotive systems, PCBs enable the functions we often take for granted.

PCBs help reduce manufacturing costs by streamlining assembly and improving reliability. The ability to produce large quantities of consistent, high-performance PCBs makes electronics more affordable and efficient.

By eliminating the need for complex wiring and offering precise control over electrical signals, PCBs improve the reliability and efficiency of devices. Whether it’s a smartphone or a microwave, PCBs ensure that our electronics work as expected.

PCBs are essential to modern electronics, enabling compact, reliable, and efficient devices. From smartphones to aerospace systems, PCBs power countless technologies. Their role continues to grow as they evolve with technological advancements. At Ruomei Electronic, our high-quality PCBs enhance product performance, providing value and efficiency for various industries.

As you plan your next electronic product, consider how choosing the right type of PCB can enhance both performance and cost-efficiency. Investing in high-quality PCBs now can save you from costly redesigns later.

A: A Printed Circuit Board (PCB) is a flat board used to support and connect electronic components. It routes electrical signals and power using conductive copper traces, making devices functional and efficient.

A: PCBs are essential in consumer electronics like smartphones and computers. They enable compact design, high performance, and reliable operation by connecting critical components.

A: In medical devices, PCBs ensure accuracy, reliability, and safety. They support critical equipment like heart monitors and pacemakers, meeting strict standards for performance.

A: The cost of manufacturing PCBs depends on factors like complexity, material, and quantity. High-quality PCBs for advanced applications may cost more but ensure better reliability and performance.