Views: 0 Author: Site Editor Publish Time: 2025-12-24 Origin: Site

Surface-mount technology (SMT) is key in modern PCB manufacturing. It enables faster, smaller, and more efficient devices.

In this article, we’ll explain what SMT stands for, how it works, and compare it to older technologies like THT.

At Ruomei Electronic, we provide top-quality SMT solutions for modern electronics. Learn more about our products today.

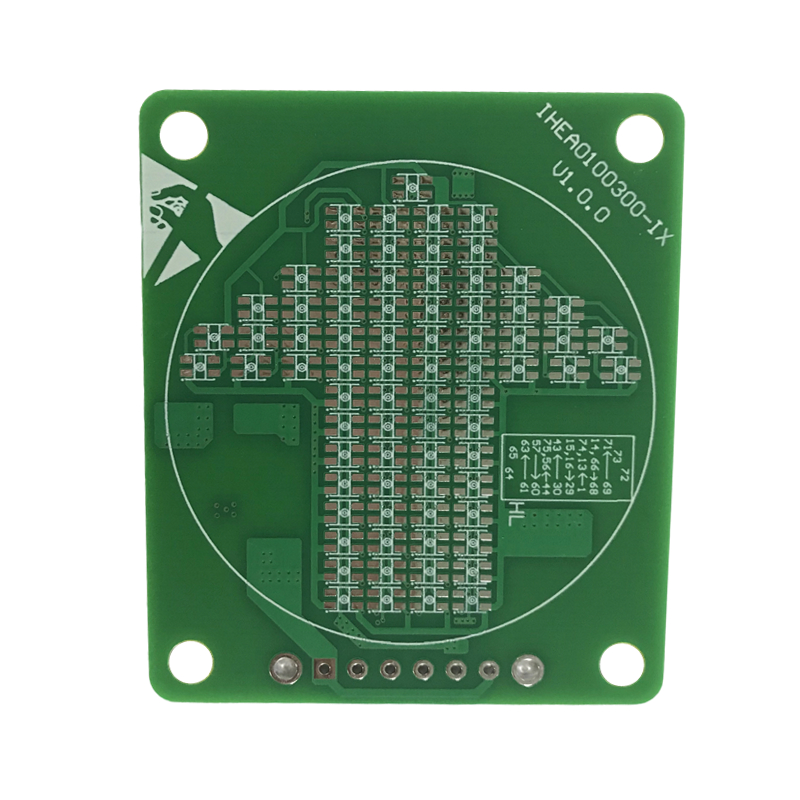

SMT stands for Surface-Mount Technology. It is a process used to attach electronic components directly onto the surface of a printed circuit board (PCB) rather than inserting them through holes in the board. This method uses smaller, more efficient components that are mounted flat on the board, enabling more compact and high-density designs. SMT components have shorter leads, or no leads at all, which makes them suitable for smaller devices that require space-saving solutions.

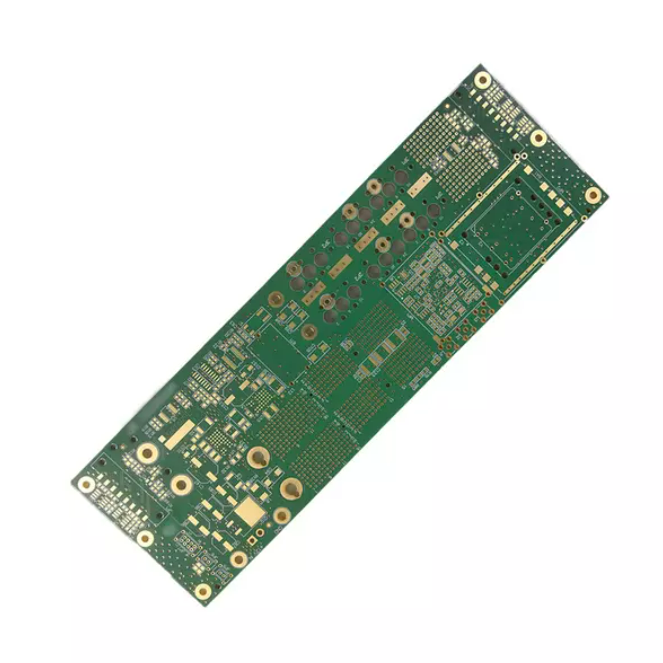

SMT differs from traditional through-hole technology (THT) in the way components are mounted. In THT, components have leads that pass through holes in the PCB and are soldered on the opposite side. In contrast, SMT components sit on the surface of the PCB, eliminating the need for holes and enabling quicker assembly processes. This key difference allows for better space utilization, higher component density, and more efficient manufacturing.

The process begins with the application of solder paste to the surface of the PCB. This paste, which consists of fine metal particles suspended in a flux, is applied to the pads where components will be placed. A solder paste stencil is often used to apply the paste accurately and uniformly, ensuring that only the required areas are covered.

Once the solder paste is applied, components are placed on the PCB using a pick-and-place machine. These machines are highly automated and can place thousands of components per hour. The accuracy and speed of this machine allow for high-density circuit boards with tiny, precise components. The placement is done in real-time under controlled conditions to ensure that components align properly with the pads.

After placement, the PCB enters a reflow oven. The reflow process involves heating the board to a temperature where the solder paste melts and forms a strong electrical bond between the component leads and the PCB pads. The board is gradually cooled, solidifying the solder and securing the components in place. This process is critical to ensuring high-quality, reliable solder joints.

Step | Description |

Solder Paste Application | Apply solder paste to PCB pads using a stencil to prepare for component placement. |

Component Placement | Automated pick-and-place machine places components accurately onto the PCB. |

Reflow Soldering | The PCB passes through a reflow oven where solder paste is melted to bond components. |

Inspection | Visual and automated optical inspection (AOI) to ensure proper placement and soldering. |

One of the most significant advantages of SMT over THT is the speed of the assembly process. SMT allows for automated component placement, which is faster and more accurate than manual placement used in THT. This high-speed process results in quicker turnaround times, which is ideal for high-volume production.

SMT components are smaller and require less space than their THT counterparts, which allows for higher component density on a PCB. This makes it possible to create more compact and lightweight electronic devices. For example, modern smartphones and tablets benefit greatly from SMT, as it enables them to house more powerful components in a smaller form factor.

SMT components are attached with a soldering process called reflow soldering, which generally results in stronger and more reliable joints. This process ensures that the solder joints are evenly distributed and free from defects, improving the overall durability and reliability of the PCB.

Benefit | Description |

Higher Component Density | SMT enables a higher component density, ideal for compact electronics. |

Improved Reliability | SMT components are more reliable and durable due to better soldering methods. |

Faster Production Speed | Automated placement of components reduces assembly time and improves production efficiency. |

Cost Efficiency | With fewer manual processes, SMT reduces labor costs and material wastage. |

Passive components like resistors, capacitors, and inductors are essential in most PCBs. In SMT, these components are available in smaller, more efficient forms, making them ideal for compact designs. For example, surface-mount resistors are significantly smaller and can be placed at a higher density compared to through-hole resistors, contributing to space savings on the board.

Active components, such as diodes, transistors, and integrated circuits (ICs), play a crucial role in controlling the flow of current within the circuit. SMT enables these components to be smaller, which allows manufacturers to pack more functionality into a smaller, more powerful space. Integrated circuits (ICs) like microcontrollers, microprocessors, and power management ICs are all commonly used in SMT assembly.

Proper placement of components is vital for ensuring that the PCB functions as intended. Components must be strategically placed to minimize the length of the electrical traces, reduce electromagnetic interference (EMI), and optimize the thermal performance of the board. Components such as decoupling capacitors should be placed near power pins, and high-frequency components should be positioned in ways that reduce noise.

The design of PCB pads, where components connect to the board, is essential for a successful SMT assembly. The pads must match the component specifications to ensure a secure solder joint. An improper pad design can lead to poor solder joints, leading to electrical failures. A well-designed PCB layout helps ensure efficient soldering, reduces defects, and improves the overall yield of the manufacturing process.

The reflow soldering process is highly sensitive to temperature variations. An improperly controlled temperature profile during reflow can result in solder defects such as tombstoning, where components are partially lifted off the board, or cold solder joints. The temperature profile must be optimized to match the component’s and the PCB’s material requirements.

SMT is faster and more efficient than THT, particularly in mass production settings. With fully automated machines, SMT can process large volumes of PCBs in less time, reducing labor costs and lead times. THT, by contrast, often involves manual insertion and soldering, which can slow down production.

Feature | SMT (Surface-Mount Technology) | THT (Through-Hole Technology) |

Component Size | Smaller components, ideal for high-density designs | Larger components, suitable for high-power applications |

Production Speed | Faster assembly due to automation | Slower due to manual processes |

Reliability | More reliable solder joints, better for high-frequency circuits | Stronger mechanical support for large components |

Assembly Process | Fully automated with pick-and-place machines | Manual insertion and soldering of components |

Cost Efficiency | Lower overall production cost due to automation | Higher labor costs and longer assembly times |

SMT excels at handling small, compact components. For components that require more substantial mechanical support, such as large connectors or heavy-duty capacitors, THT is still the preferred method. However, for most modern electronic devices, SMT is ideal due to its ability to handle dense, high-performance components.

SMT is suitable for compact consumer electronics where space is a premium. It’s used in smartphones, laptops, and other devices where size and performance are crucial. On the other hand, THT is ideal for applications in industrial machinery or power electronics, where components experience greater mechanical stress and need stronger soldering connections.

SMT was developed in the 1960s as an alternative to through-hole technology. Initially, the process was expensive, and component availability was limited. However, as manufacturing processes advanced and technology improved, SMT became more accessible and affordable, leading to widespread adoption.

By the 1990s, SMT had become the standard in consumer electronics. The introduction of smaller, more reliable components made it possible to create devices like smartphones and laptops with far greater functionality and portability than ever before. As consumer demand for compact, high-performance devices grew, SMT was at the forefront of meeting that need.

With the rise of emerging technologies such as 5G, IoT, and AI, SMT will continue to evolve. These technologies demand even more compact and efficient designs, and SMT is adapting to meet these needs. Expect even smaller components, faster production methods, and more advanced techniques to drive further innovations in the coming years.

Surface-mount technology (SMT) has revolutionized PCB manufacturing by enabling faster, more efficient, and compact designs. It plays a key role in modern electronics, driving innovation in consumer products and telecommunications. With benefits like higher production speeds, better component density, and improved reliability, SMT is crucial for creating high-performance devices. Understanding the SMT process ensures the production of high-quality, reliable, and cost-effective PCBs.

Ruomei Electronic offers top-quality SMT solutions that meet the growing demands of modern electronics, helping to enhance product performance and efficiency.

A: SMT stands for Surface-Mount Technology, a method of mounting electronic components directly on the surface of a PCB.

A: SMT offers faster production, higher component density, and more reliable solder joints compared to traditional through-hole technology (THT).

A: SMT improves PCB assembly by enabling automated placement of components, speeding up production, and reducing labor costs.

A: SMT uses components like resistors, capacitors, ICs, and connectors, all designed for surface mounting with no or minimal leads.