Printed Circuit Board (PCB) warping is a common yet critical problem in electronics manufacturing. It can severely impact product quality and reliability. Warped PCBs lead to misalignments, soldering defects, and long-term mechanical stress.

In this article, we will explore the causes of PCB warping, how to prevent it, and how to fix it if it occurs.

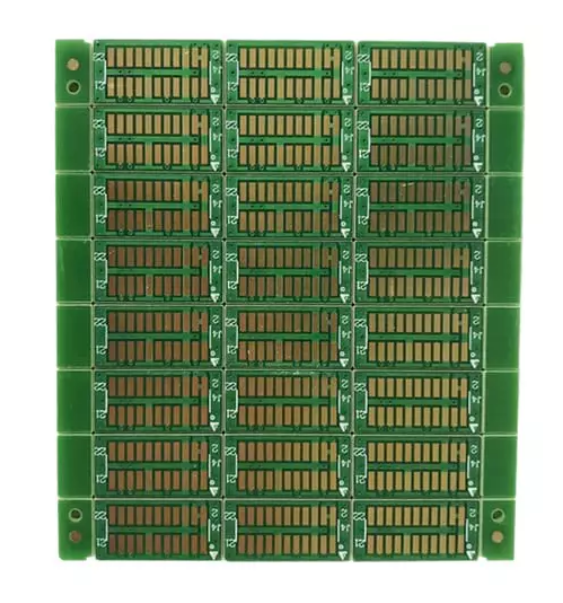

PCB warping refers to the bending or twisting of a printed circuit board, causing it to deviate from its original flat shape. Warped PCBs can lead to misalignment during the assembly process and cause significant defects in the final product. Understanding the different types of warping is important to recognize the problem early and take corrective actions.

PCB warping occurs when the board experiences stress during its manufacturing process, causing it to lose its flatness. Common signs of PCB warping include visible bending, twisting, or lifting edges when placed on a flat surface. It can also manifest as an uneven board surface, which can affect the accuracy of automated assembly machines like pick-and-place systems.

There are two main types of PCB warping: bowing and twisting. Bowing occurs when the board curves along its length or width, creating a concave or convex shape. Twisting, on the other hand, involves the board twisting along its diagonal, often causing one side to lift higher than the other. Both types of warping can cause alignment issues during assembly and soldering.

Understanding the causes of PCB warping is essential for identifying effective solutions. The warping process can be attributed to several factors, including the choice of materials, manufacturing processes, and design flaws.

One of the primary causes of PCB warping is the mismatch between the materials used in the board’s construction. A PCB typically consists of multiple layers of copper, resin, and other materials, each with different thermal expansion coefficients (CTE). When these materials expand at different rates under heat, stress builds up within the layers, leading to warping. Ensuring that the materials used in the PCB are compatible with each other and have similar CTE values is crucial for minimizing the risk of warping.

Thermal stress occurs when the PCB undergoes temperature fluctuations during manufacturing processes such as soldering and lamination. High temperatures, especially during reflow soldering, cause the PCB to expand. If the board is not evenly heated, the differential expansion between different areas of the PCB can cause warping. This stress can accumulate over time, particularly in multi-layer PCBs.

Uneven copper distribution on the PCB can also contribute to warping. Copper layers in the PCB expand at different rates depending on the amount of copper present. When there are imbalances, such as one side of the PCB having more copper than the other, it leads to uneven expansion and causes the board to bend. Similarly, heavy components placed asymmetrically on the board can cause uneven stress distribution, exacerbating the warping problem.

Cause | Description |

Mismatched Material Properties | Different Coefficient of Thermal Expansion (CTE) values cause internal stress. |

Thermal Stress | Temperature variations during production, such as soldering or lamination, cause warping. |

Uneven Copper Distribution | Uneven copper coverage leads to imbalanced thermal expansion, resulting in warping. |

Improper Component Placement | Uneven weight distribution or concentration of components can cause localized warping. |

The PCB manufacturing process plays a critical role in determining whether or not the board will warp. Key steps in the manufacturing process, such as soldering, lamination, and pressing, must be carefully controlled to prevent warping.

Improper temperature control during soldering can lead to PCB warping. During reflow soldering, the PCB is subjected to high temperatures, which cause the materials to expand. If the heating process is not uniform, or if the PCB is subjected to rapid temperature changes, it can cause uneven thermal expansion, resulting in warping. It’s essential to use controlled temperature profiles during reflow soldering to prevent thermal stress.

Lamination involves bonding layers of the PCB together under heat and pressure. If the pressure is not applied uniformly, or if the temperature is not carefully controlled during the lamination process, the board can warp. Uneven pressure during pressing can cause internal stress that leads to warping, particularly in multi-layer boards.

While it’s nearly impossible to prevent all instances of PCB warping, there are several strategies manufacturers can implement to minimize the risk. Proper design, material selection, and process control are key to reducing the likelihood of warping.

A well-designed PCB can significantly reduce the risk of warping. Ensuring a balanced copper distribution across the board is crucial. Designers should also pay attention to the layer stack-up of multi-layer PCBs. A symmetric stack-up minimizes internal stresses that can lead to warping. Additionally, designers should avoid placing heavy components on one side of the board, as this can create an imbalance that leads to bending.

Choosing the right materials is critical for preventing warping. High-TG (glass transition temperature) materials tend to have more thermal stability, which reduces the risk of warping during high-temperature processes. Additionally, selecting materials with compatible thermal expansion properties ensures that the different layers of the PCB expand and contract at similar rates, reducing internal stress.

During the manufacturing process, it’s essential to control temperature gradients and apply consistent pressure. For example, during lamination, applying uniform pressure and temperature helps ensure even curing of the materials, reducing the chances of warping. Similarly, in the reflow process, ensuring gradual and controlled temperature changes prevents sudden expansions that lead to warping.

Prevention Method | Explanation |

Optimize PCB Design | Ensure balanced copper distribution and layer symmetry to reduce warping risk. |

Material Selection Best Practices | Choose materials with stable thermal expansion properties to prevent deformation. |

Temperature and Pressure Control | Manage thermal gradients and ensure even pressure during production processes. |

Detecting PCB warping early in the manufacturing process is crucial to minimizing defects. Several methods are available to measure warping in PCBs, ranging from simple manual inspections to more advanced automated systems.

The simplest method for detecting PCB warping is by placing the board on a flat surface and visually inspecting it for any irregularities. A ruler or straightedge can also be used to check for gaps or unevenness in the surface. However, this method may not detect small or subtle warps.

For more precise measurements, automated systems like Automatic Optical Inspection (AOI) and 3D scanning can be used. These systems can detect even minor deviations from flatness and provide detailed information about the extent of warping. AOI systems use cameras and sensors to analyze the surface of the PCB, while 3D scanning creates a digital model of the board to detect dimensional inaccuracies.

Method | Tools/Explanation |

Visual Inspection | Check for visible bends or lifted edges by placing the PCB on a flat surface. |

Ruler or Straightedge Test | Use a ruler or straightedge to check for gaps or uneven surfaces. |

Automated Inspection (AOI, 3D Scanning) | Use advanced systems like AOI or 3D scanning for precise measurements. |

While some minor warping can be corrected, severely warped PCBs are often beyond repair and must be discarded. However, there are several methods available for fixing small warps.

If the warping is minor, it can sometimes be corrected through re-baking and cold pressing. Re-baking involves heating the PCB to a specific temperature to release any trapped moisture and allow the material to relax. Cold pressing is then used to apply even pressure to flatten the board.

If the warping is too severe to correct or if the board does not meet the required flatness standards, it should be scrapped. According to IPC-A-600 standards, a PCB should not warp more than 0.75% of its length, and if this threshold is exceeded, the board should be discarded.

Fix Method | When to Use | Tools Needed |

Re-bake the PCB | For moisture-induced warping | Oven |

Cold Pressing | After re-baking to cool the PCB evenly | Flat press |

Manual Flattening | For minor warps, gently press by hand | Flat surface, hands |

Replace Severely Warped PCBs | If warping cannot be fixed through other methods | None |

PCB warping can lead to significant cost implications for manufacturers, affecting production efficiency and product quality.

Warped PCBs can increase manufacturing costs due to the need for rework or scrapping. The additional labor and materials required to fix warped boards can add up quickly, impacting the overall production budget. Moreover, the cost of delays and increased inspection times can further drive up expenses.

Warped PCBs are more likely to experience reliability issues over time. Warping can lead to mechanical stress on components and solder joints, potentially causing failures in the field. This can lead to increased warranty claims, returns, and damage to the manufacturer’s reputation.

Understanding the causes and prevention methods of PCB warping is vital for ensuring product quality and reliability. By optimizing PCB design, selecting the right materials, and controlling the manufacturing process, manufacturers can minimize warping risks. Regular inspections and precise detection allow early corrective actions. Preventing warping not only reduces production costs but also guarantees high-quality standards.

Manufacturers should review their design and production processes, ensuring best practices are followed to avoid costly defects and enhance product reliability. For companies like Ruomei Electronic, adopting these practices ensures optimal performance and lasting product quality.

A: PCB warping can occur due to mismatched material properties, thermal stress during production, uneven copper distribution, or improper component placement.

A: To prevent PCB warping, optimize your PCB design, select the right materials, and control temperature and pressure during manufacturing.

A: Minor PCB warping can sometimes be fixed with re-baking or cold pressing, but severely warped PCBs should be discarded to maintain quality.

A: You can measure PCB warping using visual inspection, rulers, straightedges, or advanced tools like Automatic Optical Inspection (AOI).

A: Choosing materials with stable thermal expansion properties ensures that PCBs can withstand heat without warping, improving product reliability.